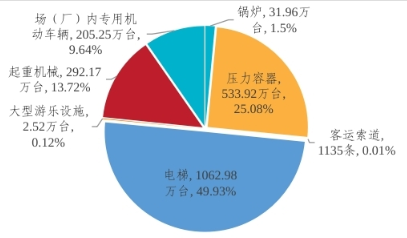

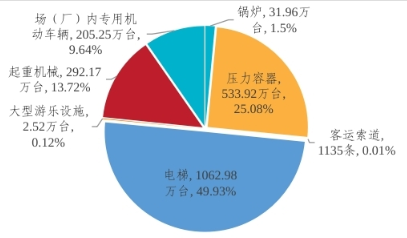

On April 1, 2024, the State Administration for Market Regulation issued a notice on the safety status of special equipment in the country in 2023, and by the end of 2023, the total number of special equipment in the country will reach 21.2891 million units, including 2.0525 million special motor vehicles in the field (factory).

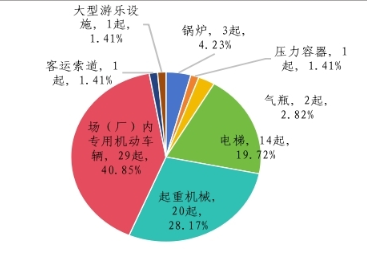

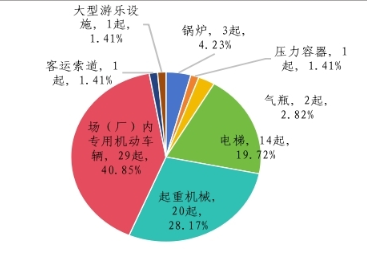

In 2023, a total of 71 special equipment accidents and related accidents occurred across the country, resulting in 69 deaths. Among them, the accidents of special motor vehicles, lifting machinery and elevators in the field (factory) accounted for a relatively large proportion, accounting for 88.73% of the total number of accidents and 86.96% of the total number of deaths.

According to the link where the accident occurred, 60 occurred in the use link, accounting for 84.51%; 9 cases in the maintenance link, accounting for 12.68%; 1 installation and commissioning link, accounting for 1.41%; 1 was in the transportation link, accounting for 1.41%.

According to the analysis of the materials of many closed cases in 2023, the causes of the accident are mainly divided into the following two categories

1. Improper use and management, such as illegal operation, unlicensed operation, management negligence, etc

2. The failure of safety components or the failure of protective devices caused by inadequate maintenance and maintenance of equipment.

In view of the above problems, the fleet management system (FMS) developed by the Shanghai Litu team can be perfectly solved.

The system can help the management to obtain forklift status information more conveniently through PC or smart phones, including pedestrian warning time, analyze and evaluate dangerous behaviors, manage forklift operations more efficiently and improve overall work efficiency.

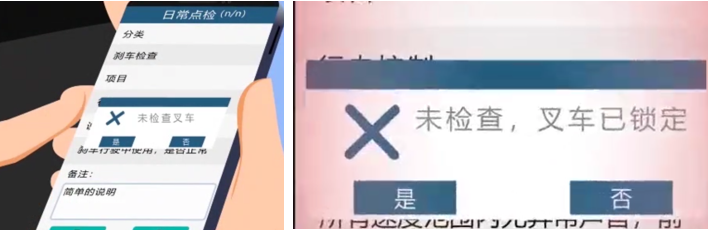

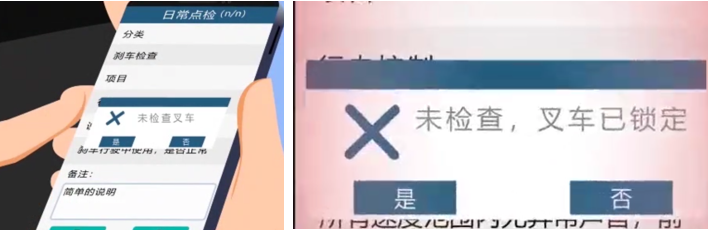

1. Spot check and intelligent start-up

Operators need real-name qualification authentication, card power on, and face recognition.

Employees need to complete the appearance inspection, operation inspection, brake inspection, etc. according to the prompts of the APP, and if the inspection is not completed according to the prompts, the forklift will not be able to start.

2. Collision detection

When the vehicle collides, the vehicle number, personnel identity and time are automatically recorded, and the management personnel will receive the forklift status reminder email, and they can choose to lock and stop the forklift operation after the collision on the computer or mobile phone, and the management personnel need to unlock it after locking.

3. Forklift utilization rate and driver efficiency

The system will record the operation process of the forklift, such as the time of switching on and off, the operation time, the mileage traveled and the number of loads, etc., and generate these data into an intuitive and clear table for managers to view on their mobile phones or computers

The system has the function of generating data reports and analyzing data, docking with ERP, WMS, MES systems, it can grasp key data in real time, improve forklift efficiency and improve forklift safety, and use big data to improve management and optimize paths.

Not only that, no matter where the warehouse is located in the world, the administrator can keep the fleet in the best condition through one-click operation management on mobile devices (to help managers better optimize the entire fleet).

4. Forklift maintenance management

Event reminder function: the system automatically reminds forklift maintenance, forklift annual inspection and personnel operation certificate, as well as personnel operation certificate and equipment expiration reminder.

5. Battery monitoring

Battery monitoring function: battery status monitoring, timely reminder when water shortage and high temperature, complete recording of charging and discharging time, hydrogen and smoke alarm devices in the forklift charging room can be implemented to detect fire risks and prevent fires.

In 2024, Shanghai Litu Logistics will continue to conscientiously implement the decision-making and deployment of the Party Central Committee and the State Council and the work requirements of the Party Group of the General Administration, deeply grasp the general idea of "stressing politics, strengthening supervision to promote development, and ensuring safety", make every effort to keep the bottom line of special equipment safety, and continue to create a good safety environment for high-quality development.

1. Keep the "one bottom line" and strengthen the safety supervision of special equipment

2. Introduce "two regulations" to consolidate the main responsibility of enterprises

3. Promote the "three supervisions" and improve the efficiency of special equipment supervision

4. Promote the quality improvement of the special equipment industry and strengthen the cultural construction in the field of special equipment